What is cable trays and why we use a cable tray?

What is cable trays and why we use a cable tray?

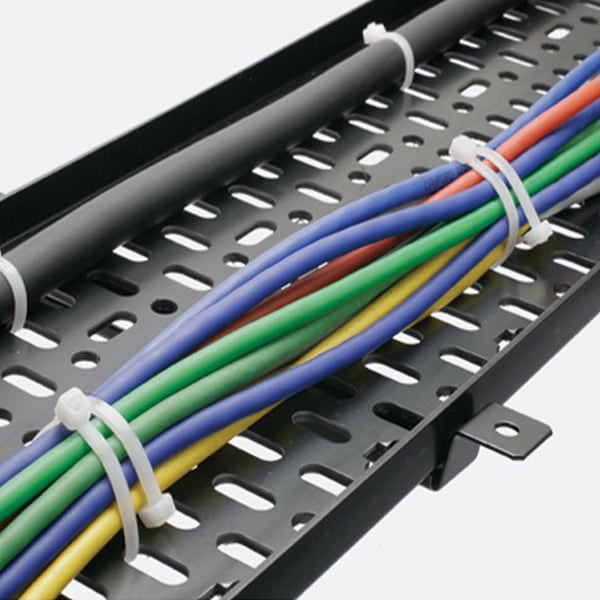

In the world of new technology, the cable tray is one of the most widely used and simplest technological achievements that we are observing today. To better understanding about what a cable tray is, we draw your attention to the rest of the article. Cable tray can be used in electrical wiring of factories, commercial centers, buildings, high-tech construction-office centers. The cable tray allows a large number of cables, in addition to being protected, to pass through a regular and integrated path without creating an ugly view and the potential dangers of access and interference. This makes it easier to access the collection wiring. Despite the cable tray, it is very useful, especially when replacing, modifying, or repairing part of the wiring, and makes the job much easier.

The cable tray allows a large number of cables, in addition to being protected from dangers, to pass through a regular and integrated path without creating an ugly view and the potential dangers of access and interference. This makes it easier to access the collection wiring. Despite the cable tray, it is very practical, especially when replacing, modifying, or repairing part of the wiring, and makes the job much easier. There are many types of cabling in factories and industries. To keep the beauty of the environment and the order of these cables, you can use a cable tray. By installing the cable tray in the same direction, the cable tray can also be considered as a place to install the moonlights.

Cable Try

Cable Try

The cable tray is used to respond to recent technology changes and is easy to install. An important point that distinguishes the use of a cable tray from the use of other tools is its quick and very easy installation. Using a cable tray to run the wiring can be very economical. The cable tray creates an order in the wiring and the safe passage of wires or cables in the open wiring system. The cable tray can greatly protect a building set from the dangers of wiring such as fires and connecting wires and cables. In fact, this simple technology is produced in different dimensions and models and in very light weights, through which it is easy to control and wiring the entry or exit of new or existing wires in the system. These cables pass through the cable tray along the route, depending on the type of route and the equipment used for the cable tray vertically or horizontally or curved.

Why is it important to use a cable tray?

Why is it important to use a cable tray?

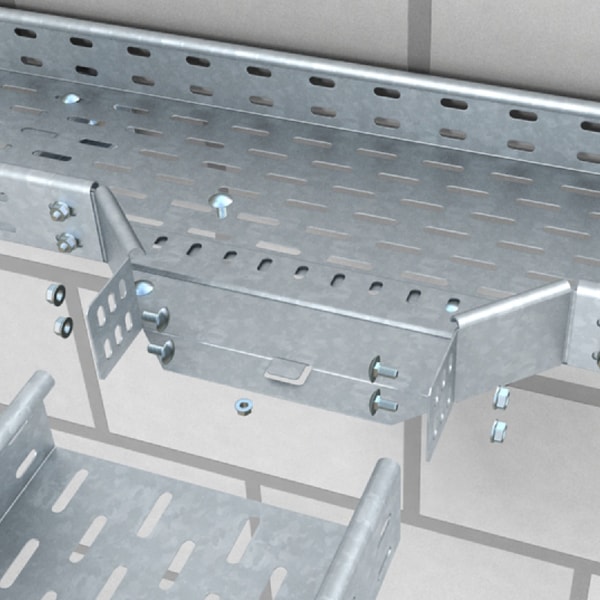

A standard cable tray can be used to create a layer of physical protection that provides a very safe and complete path for a large number of wires or cables to power, network, telecommunications, etc. on the roof or floor. A unit or set of units or sections and connections that is implemented and put into operation in a single and integrated structural system. The cable tray securely and securely supports various cables and wires and their connection path. The use of cable trays is very useful in large companies and complexes for easy installation that we mentioned. In this way, the path of the cables can be easily changed. Using a cable tray, new cables can be added to the wiring system.

What are the components of a cable tray?

What are the components of a cable tray?

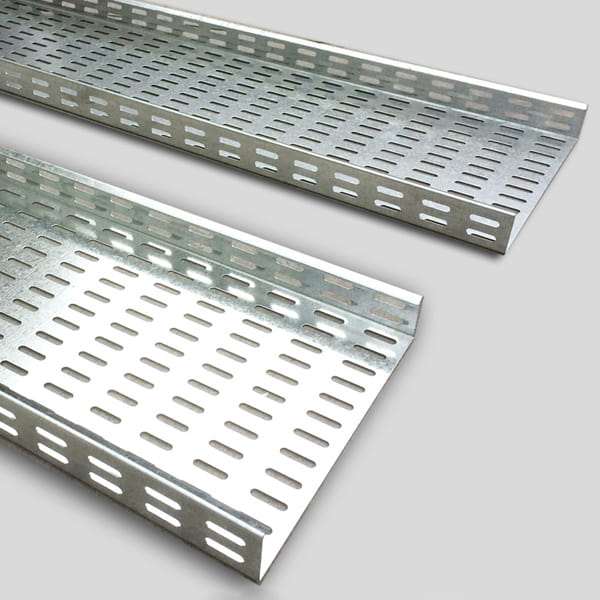

Cable trays are made of galvanized steel, stainless steel, aluminum or compressed plastic. To protect the cables and make the wires pass easily and securely in the electrical industry, a cable holder called a cable tray is used. Galvanized sheet or GRP or steel is commonly used to make a cable tray. They use fabric galvanized materials for roofed environments such as sheds and parking lots, for outdoor environments, it is better to use plated material. In fact, by consulting with professionals about your desired project, you can make the right decision on which of these cable trays should be selected and used based on the type of location and its application in the desired collection or project. This means that the installation environment and issues related to corrosion and electrical conditions play a major role in choosing the type of cable tray. With the right advice and choice, you can avoid making the next expense by making the wrong choice.

What are the types of cable trays?

What are the types of cable trays?

The cable tray is produced in widths of 5, 10, 15, 20, 25, 30, 40, 50 and 60 cm and the heights of 4, 5, 6, 8, 10 and 15 cm and in branches of 2 and 3 meters. It is usually possible to choose the cable tray door from a thinner sheet than the tray itself, in order to reduce the purchase cost. In general, cable trays are divided into 5 categories: Cold galvanized cable tray. Hot galvanized cable tray. Colored cable tray. Steel cable tray. Plastic cable tray or PVC.

Hot and cold galvanized cable tray:

Hot and cold galvanized cable tray:

In areas with high humidity and chemical corrosion, hot-dip galvanized cable trays, such as hot plating, are used for protection. The creation of this protective layer of metal makes it durable and stable. In the north and south of Iran, due to the presence of moisture and sultry environments, the hot plating type of these trays is used. It is produced in such a way that the galvanized oiled or black galvanized sheets are dipped after cutting and the response operation in plating tubs filled with tin and zinc. Zinc-lime solution can be used to prevent corrosion of cut parts.

In contrast to low humidity and corrosion, cold plating is used instead of hot, and galvanized thickness will be lower.

In many cases, galvanized cable trays are used in factories, passages, parking lots and sheds. This makes it easier to access the cables if you need to increase and decrease the wires, as well as the high speed when installing the cable tray. Cold galvanized cable trays are commonly used for these locations. The materials used for making metallic cable trays are plain carbon steels & Stainless steel. The average standard for galvanizing sheets is 45 to 65 micrometers, which is acid-washed by the technical plating department according to the Astm A153 standard and enters the caoting process. The tester shall test 10 to 20 points of each trays, ladders or junctions.

There are two very important points in the process of producing cable trays:

• Abstract quality of coating.

• The thickness of coating layer in which zinc diffuses in substrate steel.

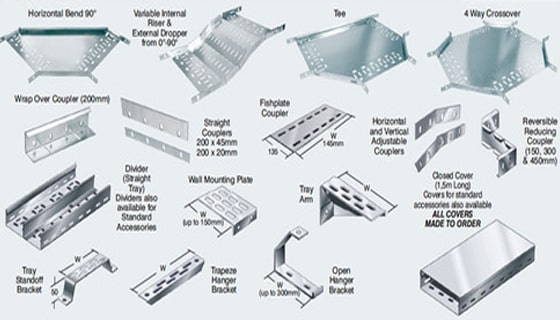

The type of sheet and bending of the cable tray is one of the important factors of its quality that should have a 90-degree angle. There should be no excess pleats inside and on the cable tray. Inside pleats injuries can cause cables to electrical hazards and short circuit connections, and on the outside of the door does not fit properly or may cause skin injuries during installation. The standard cable trays produced without any unnecessary components during installation makes it easy to use the connections including the interfaces, armpits, three-way and knee to increase the speed of installation and executive operations of the project. Usually, galvanized trays lid doors are produced from sheets with a thickness less than the cold galvanized cable tray connection sheets themselves. The cable tray doors are making on both punch-free and have a punch.

Colored cable tray:

Colored cable tray:

If you need an existing cable tray and in this regard, you can use this age-old cable model to watch enough to provide user and beauty services.

For manufacturers of colored cable trays (static colored cable trays), at the beginning, the steel sheets cut in adequate. After punching and bending, static powder paint sprays on it. In the quality provided for the manufacturers, the colored galvanized cable tray is given inside the curvature and gives its color.

individual features of this type of cable trays are:

High concentration coating.

Moisture resistance.

Resistant to heat and radiation UV sun.

Stainless Steel cable tray:

Stainless Steel cable tray:

The stainless steel cable trays are mostly made of 304 stainless steel sheets. With the use of the constitution, the possibility of being used in security forums, as well as the environment, it is possible to use the cabling systems of food factories, pharmaceutical and chemical industries. For example, in dairy factories, powerful shovels are always needed to sterilize the hat. In this description, you can use the stainless cable tray. stainless steel cable tray can display more beautiful representative in the environment, it can differentiate you from other cable trays as having higher and more strength in the field of food preparation, etc. Due to the above, it has increased its price and you can think about using it. Manufacturers of Stainless Steel Cable trays almost use stainless steel sheets thicknesses of 1 mm to 1.5 mm. Stainless steel cable trays is made in a variety of punched and without the punch types.

Plastic or PVC cable tray:

Plastic or PVC cable tray:

The weakest type of PVC cable tray, which is medium and now you can easily buy it, but this type of tray can be used to prepare a set of different cables and as Sample, ideal and modified in wiring to a very strong material. The use of optical fiber transmission is sensitive to the use of PVC trays.

The PVC tray machine is sensitive to the transmission of optical fibers. The advantage of this model is the cable tray installed on the wall of the ester and the brother. The photo of the basket cable tray, which can open the holes and the distance between each step, is briefly at the beginning, end and upper part.

PVC provides you with more power for light and sensitive cables, enabling cables to access if you wish.

This is the type of cable tray that is easily accessible and also provides you with the beauty of the press.

Cable tray applications and variety of types and its sizes:

Cable tray applications and variety of types and its sizes:

The cable trays can be used to held cables and wires to provide better presentation in constructions, buildings, factories and they considered as building materials in reputable perspectives. These cable trays can be used for cabling Internet networks and power grid management. Different cables are produced in different sizes depending on the variable size of the cables, which makes it very necessary to use them in large complexes, such as industrial sites and factories where the number of electrical devices is high. The cable tray is made in 100-150 mm widths. Therefore, depending on the width of the cable tray, the interface and support or the same holder is made. The thickness of the sheet used in the cable tray with 150 mm to 450 mm width and a height of 40 mm must be 1.5 or 1.25 mm. In a cable tray with a width of 500 or 600 mm, the Thickness should be 1.5 or 2 mm. The higher the height of the cable tray it should be the thicker. For example, in the 110 mm cable tray, there should be at least 2 mm thickness. It is possible to change facilities of a building with a cable tray so that we can update it as a collection as soon as possible we need. Various accessories and connections for cable trays can help us make our project easier.

Advantages of cable tray briefly:

Advantages of cable tray briefly:

Cable trays are actually a good alternative to wiring pipes, because they are very easy to access and integrate into the wiring, and are used to control the cable as easily as possible in commercial and industrial construction. When a system needs to be modified, the cable tray is very useful. Because new cables can be installed by placing them on the tray, instead of pulling them through a pipe. They are used for electrical protection and transmission of electrical cables on the roofs of buildings or floor, and are therefore both pleasing and aesthetically. There are holes in the bottom of the cable tray that can reduce the amount of heat between the cables or wires as electricity passes through. They are non-flammable and have a variety of components that can be easily used in places with complex execution plans. There are variety of components and can be easily used in places with complex execution plans. They have high impact resistance. Also Niru Tavan’s cable trays products have a long life and high weight bearing, variety and produce in variety of sizes and also its construction is in accordance with international standards. They are resistant to humid weather and also to acidic vapors of chemicals.

Summary To answer the question "What is a cable tray" it can be introduced as follows:

Summary To answer the question "What is a cable tray" it can be introduced as follows:

The cable tray protects the cables and provides a shorter route for better and easier cabling, creating a secure and accessible structure for cables and wires that have a complex network structure.

types of Cable Tray - Classification of cable trays

Related Posts Cable Tray - Classification of cable trays

All material and intellectual rights are reserved for the NiruTavan