What is an electrical Pipe or Conduit? What is the advantage of

using a electrical Pipe or Conduit?

What is an electrical Pipe or Conduit? What is the advantage of

using a electrical Pipe or Conduit?

In today's world, there are different methods and methods for using and guiding electric electrical Pipe or Conduit. electrical Pipe or Conduit can be used to carry out your projects. Using a conduit to pass wires or cables can bring us security, quality, cost and time savings, speed, and many other benefits.

One of the most important steps in any project is to create a set of electrical systems. To do this, you can use new and innovative methods that have many advantages, such as electrical Pipe or Conduit.

There are different types of electrical Pipe or Conduit, but they are generally divided into two main categories according to the standard material used in them.

1- Metal electrical Pipe or metal conduit.

2- Non-metallic electric pipe or non-metallic conduit.

What is an electrical Pipe or Conduit?

What is an electrical Pipe or Conduit?

Electric pipe or Conduit is one of the methods used to create power transmission projects in residential and non-residential buildings, including office, commercial, factory and industrial buildings, etc. Due to their use in various locations, electrical Pipe or Conduits are widely used in the production cycle of their products. In principle, and according to the general standard, these candidacies are classified according to two main categories as metal or metal conduit and non-metallic electric tube or non-metallic conduit.

Why is it important to use Electric pipe or Conduit?

Why is it important to use Electric pipe or Conduit?

One of the most important steps in any project is to create a set of electrical systems. To do this, you can use new and new methods that have many advantages, such as Electric pipe or Conduit. Using a conduit to pass wires or cables can bring us security, quality, cost and time savings, speed, and many other benefits.

On what basis are electric pipe or Conduits classified:

On what basis are electric pipe or Conduits classified:

Conduits or electric pipe have two general categories based on the materials used in them:

1- Metal electric pipe or metal conduit:

Electric pipes or metal conduits are often made of galvanized steel, stainless steel or aluminum. Other metals are generally not used in the manufacture of electrical pipes or metal conduits.

2- Non-metallic electric pipe with non-metallic conduits:

Non-metallic (plastic) electric pipe or Conduits are used in areas where metal use is difficult (such as a hospital MRI room) or in places where there is a risk of direct contact with water. Because in contact with water, non-metallic conduit are resistant to water due to the type of material and do not suffer from rot or rust.

The important point of both models is that both of them may be rigid or flexible.

Metal electric pipe or metal conduit:

Metal electric pipe or metal conduit:

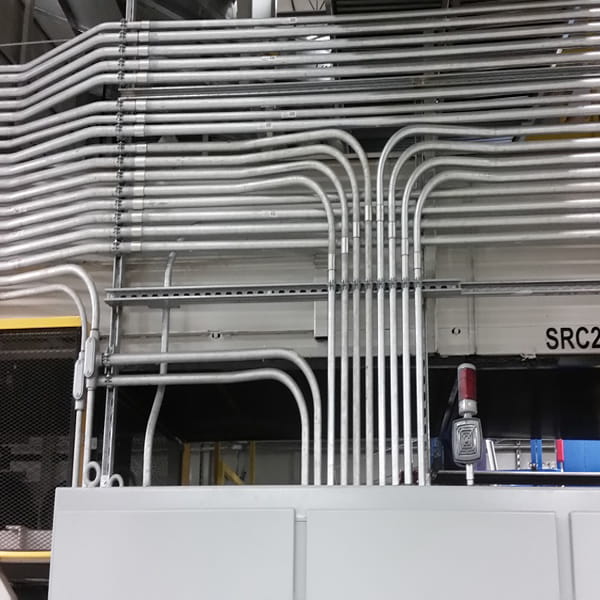

Electric pipes or metal conduits are often made of galvanized steel, stainless steel or aluminum. Other metals are not commonly used in the manufacture of conduit. They can protect people from unwanted contact with the current in the wires, as well as the wires and insulation of the wires against environmental damage. conduit creates a fully advanced infrastructure for wiring. It used a variety of locations, including non-construction sites and hotels, office buildings, commercial and commercial buildings, industries and factories, and underground facilities. In principle, metal conduit are rarely used in building or apartment wires or cables.

The principle of passing cables or wires through or metal electrical Pipe or Conduit is done according to a certain number and size according to a certain standard. This standard between wire and pipe is very important in terms of size. Metal conduit electrical Pipeline is produced by NiruTavan Abtin Company during the production process in accordance with special standards from PG11 diameter to PG48 diameter.

1- Standard UL 7971 standard in terms of protection and safety.

2- ANSI C80.3 Standard manufacturing process.

3- ASTM A123 Standard Pipe galvanizing method.

Different types of metal electrical pipes or metal

conduits based on strength standard:

Different types of metal electrical pipes or metal

conduits based on strength standard:

1- Hard metal or metal conduit Pipe (RMC).

2- Medium metal electrical pipe or medium metal conduit (IMC).

3- Flexible metal electric pipe or conduit (FMC).

Different types of non-metallic electrical pipes or

non-metallic conduit based on strength standard:

Different types of non-metallic electrical pipes or

non-metallic conduit based on strength standard:

1- Non-metallic electrical pipe or hard and non-metallic conduit (RNC).

2- Non-metallic electrical pipe or non-metallic conduit (ENT).

Types of metal electrical pipe or conduits steel:

Types of metal electrical pipe or conduits steel:

1- Hot metal galvanized electrical pipe or conduit steel (Hot Galvanized Pipe).

2- Cold metal galvanized electrical pipe or conduit steel (Cold Galvanized Pipe)

3- Metal electrical pipe or conduit colored steel (black).

4- Explosive seamless metal galvanized steel electrical pipe or conduit.

5- Flexible metal electrical pipe or conduit or flexible steel conduit.

6- Metal electrical pipe or conduit aluminum steel conduit.

7- Metal electrical pipe or conduit steel stainless .

Types of non-metallic electrical pipes or non-metallic

conduit:

Types of non-metallic electrical pipes or non-metallic

conduit:

1. Non-metallic electrical pipe or conduit pvc , which has three models

■ Hot bending electrical pipe.

■ cold bending electrical pipe.

■ fireproof electrical pipe.

2. Polyamide electrical pipe.

3. Flexible electrical pipe.

Tight or strong electrical pipe or conduit (RMC):

Tight or strong electrical pipe or conduit (RMC):

This type of conduits has tubes with thick, bandaged walls. They are usually made of insulated steel, stainless steel or aluminum. This type of metal conduit is connected to other electrical pipes by special connections. The solid metal conduit protects the wires and cables against environmental influences and hazards. Rami metal electrical pipe can be customized according to the needs and proper consultation with Nirutvan Company regarding the ongoing project. They can be made with thicker walls to prevent and protect against electromagnetic disturbances in the wiring system. Covering this conduit or metal electrical pipes with a layer of PVC or galvanized, bronze and. Can also make them resistant to decay and rust. Tubes

Medium electrical Pipe or conduit (IMC):

Medium electrical Pipe or conduit (IMC):

These types of conduits are the lightest and cheapest of the current conduits. To prevent water from entering them, they are boiled with special solvents. One of its major advantages over other metal electrical cables is that they are quick to install and easy to connect to each other. For proper bending and shaping of plastic Conduits, it can be used with the heat provided by a special tool. For special occasions where we need stronger hard drives, their walls can be thickened so that they become harder to connect.

flexible electrical Pipe or conduit (FMC):

flexible electrical Pipe or conduit (FMC):

Flexible electrical pipes are thin-walled plastic pipes that give them high flexibility. They can be easily shaped and used on high-winding routes. This type of conduit is very easy to install because it can be cut and re-welded when it encounters obstacles.

Hot metal galvanized electrical pipe or conduit steel

Hot metal galvanized electrical pipe or conduit steel

In this model, metal electrical pipes that use deep plating are mostly used in areas with humidity and open environments where there is a possibility of contact with rainwater. This model of pipe is resistant to crushing and rust and environmental factors.

The first and most important goal of hot-dip hot galvanizing is to protect the structure against corrosion, and the durability and durability of galvanized depends practically on the thickness of the layer on the protector. In the production stage, the thicker the protective layer, the longer it will last and the longer it will last for the product.

The production of hot galvanized pipes according to the following two methods and standards:

1- Sherardizing method.

2- Hot Dip Galvanized immersion method.

Cold metal galvanized electrical pipe or conduit steel

Cold metal galvanized electrical pipe or conduit steel

This model of metal electrical pipe or conduit is one of the most common types that is used more than other models.

The production of cold galvanized pipes is according to the following three methods and standards:

1. Zinc Plating or Electro Galvanizing.

2. Mechanical Plating method.

3- Galvanized method by zinc-impregnated paints by spray or brush (Zinc Rich Coating).

Metal electrical pipe or conduit colored steel (black).

Metal electrical pipe or conduit colored steel (black).

As the name implies, metal electrical pipe or conduit are used to prevent rusting in this model. They can be used indoors, in concrete. This pipe model should not be used in environments with high crushing properties and in places that are in direct contact with the ground.

This model metal electrical pipe or conduits has two salient advantages:

■ Reasonable price compared to hot galvanized pipes.

■ Convenient and convenient connections are available.

Explosive seamless metal galvanized steel electrical pipe

or conduit.

Explosive seamless metal galvanized steel electrical pipe

or conduit.

Explosion-proof electrical pipes are one of the types of pipes used in sensitive industries and explosive environments, and the price of this product is higher than other types of metal electric pipes, and it has a heavier weight than sealed pipes.

Flexible metal electrical pipe or conduit or flexible

steel conduit.

Flexible metal electrical pipe or conduit or flexible

steel conduit.

This model of pipe can be used in cases where the electric steel pipe passes through the expansion joint of the building or to connect the electricity to motors or devices that vibrate during operation. They show good flexibility during work and plastic or similar materials are used to create flexibility inside these pipes during the production stage.

UPVC electrical pipe:

UPVC electrical pipe:

It is produced in two types of cold and hot bending. Upvc pipes have a high strength and the cold bend type is bent without the need for heat and using a special spring, and is much stronger than the hot bend type.

PVC electrical pipe:

PVC electrical pipe:

This electrical Pipe model, which is made of plastic and other composite materials (softeners and lubricants), weighs less than its metal counterparts. Insulation and cheaperness are the advantages of this pipe compared to metal pipe, PVC electrical pipe is non-flammable and has many applications in the construction industry.

Polyamide electrical pipe:

Polyamide electrical pipe:

This type of pipe is made of soft plastic. These types of pipes are less expensive and more flexible than other pipes. They are currently used in small and light buildings.

flexible electrical pipe:

flexible electrical pipe:

This type of pipe is produced in three models: PVC, polyamide and metal.

■ PVC is used to pass electrical wires on the walls of the structure. These pipes bend at any angle and their components are PVC and non-flammable.

■ Polyamide is much cheaper than PVC. It bends at different angles but has little strength.

■ The metal type is used for passing electrical wires in industrial panels and exterior walls. The material of these pipes is made of PVC coating with wire to increase the strength of the pipe and its strength.

Polyethylene electrical pipe:

Polyethylene electrical pipe:

In terms of strength, these non-metallic electrical pipes are placed between the flexible and pvc pipes, which are softer than pvc pipes and stronger than flexible pipes. Can't use.

Advantages of Metal electrical pipe or conduit:

Advantages of Metal electrical pipe or conduit:

1- Metal electrical pipes are more durable than other conduit , especially non-metallic electrical pipes.

2- The metal electric pipe or conduit is resistant to the damage of vermin due to the used in its construction.

3- They have high impact resistance and pipe failure.

4- Metal electrical pipe or metal conduit is highly resistant to fire.

5- Metal electrical pipe or metal conduit is resistant to UV or ultraviolet radiation.

6- You have an almost simple task in installing, reopening and closing a metal electrical pipe or metal conduit.

7- Metal electrical pipe or metal conduit is a great way to prevent electromagnetic disturbances.

8- Using metal electrical pipes or metal conduits, cables and power cords can be well protected to avoid additional costs.

9- Metal electrical pipe or metal conduit provides good safety and protection for its maintenance officials.

10- Using a metal electrical pipe or metal conduit can be economically viable for the project at a reasonable cost and with good advice on how to choose it.

Why use a electrical Pipe or conduit?

Why use a electrical Pipe or conduit?

In short, conduits or electrical pipes can provide special safety to your project. If your project has a problem with its safety structure, it can cause you a lot of financial or human damage in the future. Electric pipes or conduits can provide us with features such as many methods in designing an implementation plan, use in different locations despite structural and environmental differences such as waterproofing or water resistance, chemical environments, environments with high humidity or pressure. Provide.

In short, to answer the question "What is a electrical

pipe or conduit" it can be introduced as follows:

In short, to answer the question "What is a electrical

pipe or conduit" it can be introduced as follows:

An electrical pipe or conduit، is a pipe used to protect and guide electrical wiring in a building or non-building structure that acts as a protective cover for conductors that have passed through it to prevent damage to the wire or its insulation, as well as Individual protection against unwanted contact with the conductor is used by electricians at the installation site of electrical equipment and for the passage of wires and cables.

Posts related to What is the definition of a electrical pipe or conduit? - What is the use of it?

All material and intellectual rights are reserved for the NiruTavan