What is the definition of an power cable? What is the difference

between an power cable and an electric wire?

What is the definition of an power cable? What is the difference

between an power cable and an electric wire?

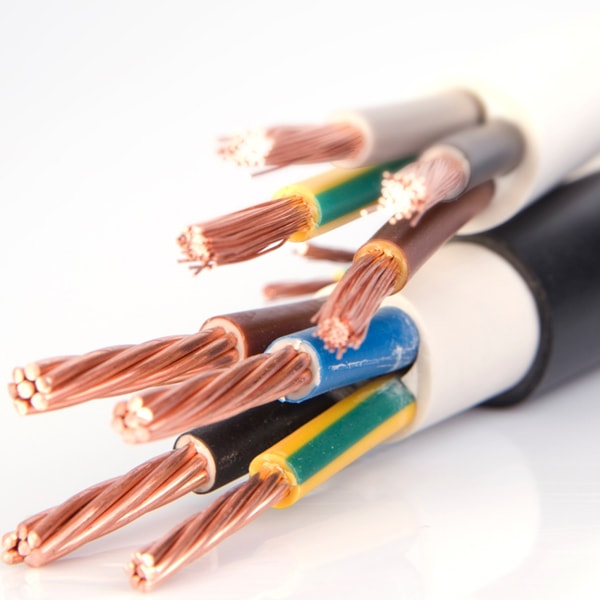

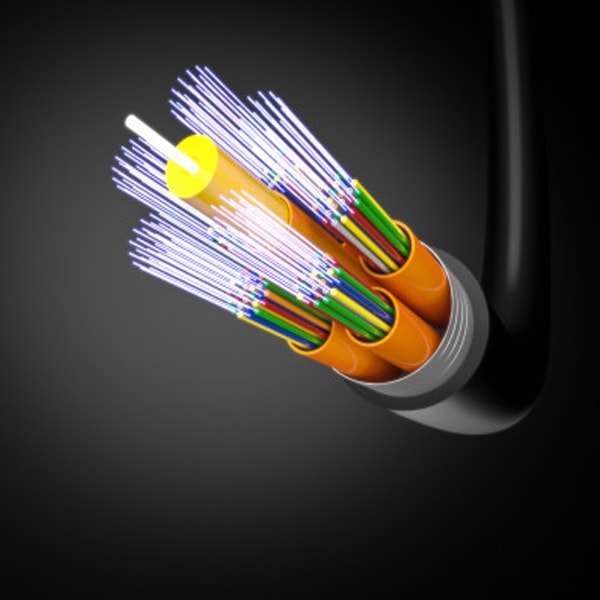

In today's world and with the advancement of technology, cables are one of the most useful human products that help humans to make life easier. Cables have a variety of applications and their effects can be found in almost all buildings, industries and types. Products such as life supplies, tools, electrical appliances, etc. were felt around him. Cables are introduced based on the type of application they have. For example, a tow cable is a type of interconnected cable from special wires used in its own industries. Cables that pass electrical conductors are called power cables. power cables are very different from cables. They are used in the telecommunications industry. Gold is the best conductor of electricity, but due to the high cost of this type of metal, it is generally used in cables to pass conductors of copper and aluminum.

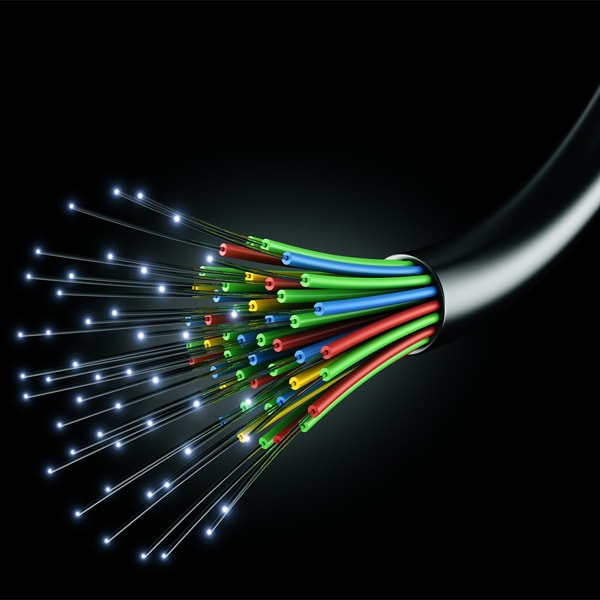

Cables consist mainly of three main components: conductor, dielectric, and sheath. The conductor in Cable provides the flow direction. Insulation or dielectric resistance is resisted by the service voltage and separates the conductor from other objects. The sheath does not allow the conductor to access the cables and protects the cables from all external influences such as chemical or electrochemical attack, fire, etc. The main components of electric power cables are described in detail below.

What is the definition of an power cable?

What is the definition of an power cable?

The cable used to transmit and distribute electrical energy is called an power cable. An power cable consists of two or more wires or electrical conductors held in a protective or insulating sheath. It is possible. It is safe to say that in the electricity industry, it is the responsibility of these wires and cables to transfer and distribute energy. Gold metal has the best electric current, but due to the high cost of this type of metal, it is commonly used in cables to pass conductors of copper and aluminum. Electrical cables are classified according to specific and many standards. These standards include use based on application, location, environmental factors, voltage value, current value, and so on.

power cable classification in a nutshell:

power cable classification in a nutshell:

power cables are classified according to the amount of pressure and voltage level as follows:

1- Fireproof cable .

2- Power Instrumentation cable.

3- Construction power cable .

4- Poor voltage power cable .

5- Medium pressure power cable .

6- High voltage power cable .6- power cable فشار قوی .

There are two categories of power cables depending on the

application:

There are two categories of power cables depending on the

application:

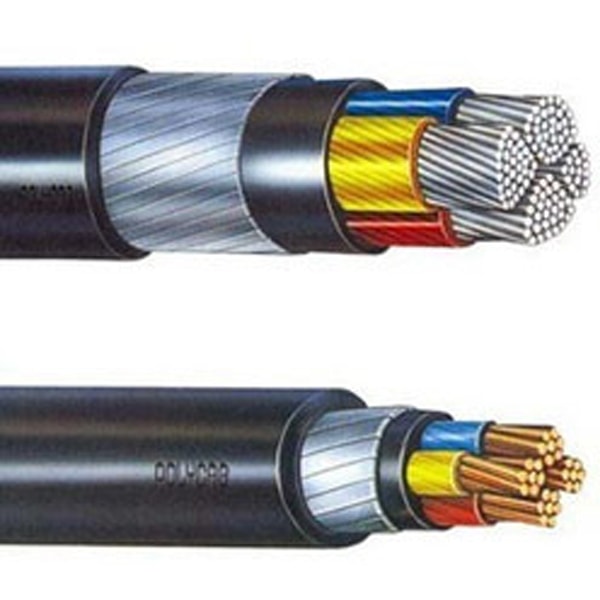

1- Armed power cable .

2- Unarmed power cable .

What is the definition of armed cable and unarmed cable?

What is the definition of armed cable and unarmed cable?

Armed Cables: Power cables that are resistant to the pressure and influence of ambient moisture and shocks and other environmental factors and have steel strips and lead coils are called armed cables.

unarmed cables: Those power cables that have a structural structure unlike armed cables and are only electrically insulated are called unarmed power cables.

Category of power cables based on the type of operation

and places used:

Category of power cables based on the type of operation

and places used:

1- Ground power cable

2- Air power cable

3- Construction power cable

What is a ground power cable?

What is a ground power cable?

This type of power cable, as its name implies, is used for places where the cable must pass through the soil and the ground, and the material used in its conduction is generally copper and has PET insulation and sheath. The wire is reinforced with steel tape.

What is an air power cable?

What is an air power cable?

These cables are used both for the bulk passage of electricity from power plants and for the specific passage of electrical voltage that must be hung in the air and on the beams. Generally, these cables use a string of galvanized steel wire under the cable sheath in line with the rest of the wires.

What is a building power cable?

What is a building power cable?

Everyone is generally familiar with this without the need for a specific description. Many of these power cables are used in construction, and the conductor is generally copper and has pvc insulation.

What is the structure of an power cable?

What is the structure of an power cable?

Building a standard cable depends on many materials. The most important features to consider are:

1- The place or location of the used power cable and its installation type.

2- The type, as well as the amount of voltage and current that is to pass through the power cable.

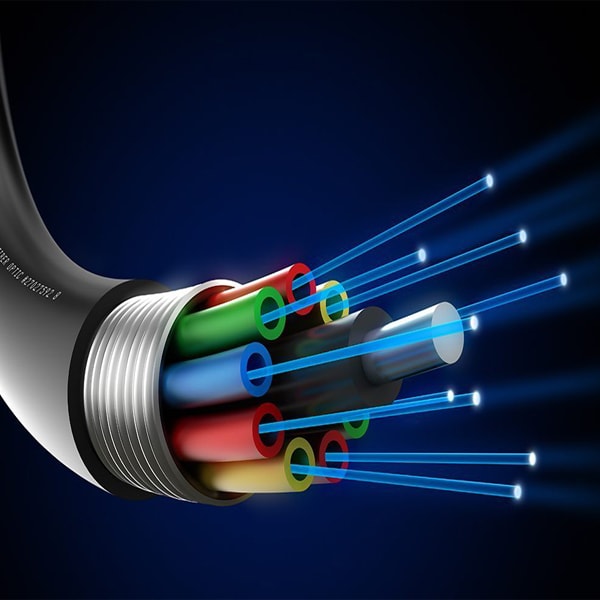

There are other things that are not the same standard for everyone, but in general, the power cable consists of two main and important parts:

1- conductor Cable

2- Cable insulation

Note: Sometimes an power cable with a cable conductor and cable insulation does not have the characteristics of a suitable cable, and for these purposes, knauf or armor and shield are used in the construction of the power cable to provide more protection. So with the above explanation, we conclude that the power cable should have four parts.

1- conductor Cable

2- Cable insulation

3- Cable or armor shield

4- shield or jacket Cable

The classification of cables varies depending on the shape, cross section, material and number of conductors, voltage, type of installation and insulation used in the cables.

What is a cable conductor?

What is a cable conductor?

In general, a conductor is needed if we want electricity to pass through a small device or to create power lines that supply an entire city. A conductor is a material that allows the electric current to pass freely. In the case of an electrical system, a "conductor" specifically refers to a piece that transmits electricity from a source to the load of a device or place of use.

When an electric charge is applied, metals provide the best conductive properties. That's why metals are the best choice for conductors in electric cables. Although we are all accustomed to using copper as the most conductive, the best metal conductor is silver. But due to the high price of silver, copper is often used. Other metals such as aluminum, gold, steel and brass are also conductive, but are not as effective as copper and silver, and the use of these metals in power cables may have other side effects. Pure that has acceptable flexibility or is made of aluminum or its special alloys.

The conductor used in the power cable has different shapes. The shape of the conductors inside the power cable is marked with the following abbreviation on the cable.

re: round single string

rm: round a few strings

Se: Single string triangle/p>

Sm: A multi-string triangle

What is cable insulation?

What is cable insulation?

Electrical cable insulation is a non-conductive material or material that is resistant to electric current. It is often called a dielectric in radio frequency cables. The insulation resists electrical leakage, prevents the wire from coming into contact with other conductors, and protects the integrity of the wire material by protecting it from environmental threats such as water and heat. The safety and effectiveness of the wire depends on its insulation. The use of insulation around a conductor in an electrical cable is used to separate the conductors. Most electrical cable insulation is made of polymer and sometimes oil-impregnated rubber. The material and number of layers are selected according to the type of power cable and its application.

The most important types of cable insulation are:

1- Polyvinyl chloride or plastic (PVC) cable insulation .

2- Semi-Rigid PVC cable insulation (SR-PVC) .

3- Polyvinyl chloride cable insulation Plenum (Plenum PVC)

4- Polyethylene cable insulation (PE)

5- Polypropylene cable insulation (PP)

6- Fluoropolymer cable insulation

7- Rubber cable insulation

8- Insulation of cable paper impregnated with special oil

The most common dielectrics in paper power cables are impregnated paper, butyl rubber, polyvinyl chloride cable, polyethylene, and cross-linked polyethylene. Paper insulation cables are preferred because their current carrying capacity is high, they are generally reliable and have a longer life.

The dielectric composition used for the cable must have the following properties:

■ Insulation must have high insulation resistance.

■ It must have a high dielectric strength so that it does not allow leakage current to pass through it.

■ The materials must have good mechanical strength.

■ The dielectric material must be able to work at high temperatures.

■ It should have low thermal resistance.

■ It must have a low power factor.

Cables used for underwater and wet soils should use synthetic dielectrics such as polyvinyl chloride, polyethylene, and so on. Also, this type of dielectric, with its good dielectric resistance, is capable of low power loss and low thermal resistance.

Electric cable inner cover:

Electric cable inner cover:

It is used to protect the cable against the moisture that affects the insulation. The cable sheath is made of lead alloy, and these resistors withstand the internal pressures of the pressurized cables. The material used for the interior coating must be made of non-magnetic materials.

Aluminum sheaths are also used in power cables because they are cheaper, lighter in weight, and have higher mechanical strength. Cables and telephones filled with oil use corrugated aluminum corrugated cables because they have better bending properties, reduced thickness and less weight.

Cable protective cover:

Cable protective cover:

Lead sheath cables are damaged by corrosion and electrolyte when placed directly on the ground. Fiber vinyl chloride is used to protect cables against corrosion layers of fiber materials such as paper, hessian, etc. The layers of fibrous material that are dispersed with the waterproof compound outside the power cable are called servers.

What is the difference between an power cable or a power

cord?

What is the difference between an power cable or a power

cord?

With all the explanations given in this section, it is easy to say that the power cord consists of one conductor, but the power cable consists of several power wires and several conductors.

Posts related to Power cable - Insulation information used in power cable

All material and intellectual rights are reserved for the NiruTavan