the definition of an electrical panel? What is What is the basis

for choosing the type of electrical panel?

the definition of an electrical panel? What is What is the basis

for choosing the type of electrical panel?

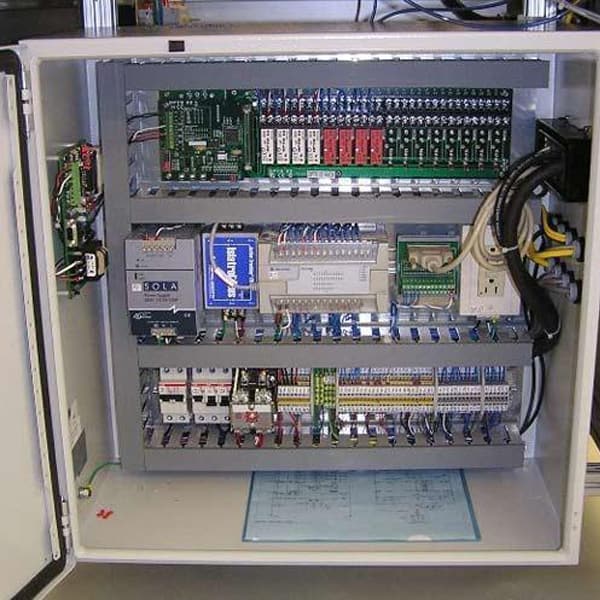

An electrical panel is a space where electrical equipment is assembled. In fact, in the electrical industry, when electrical currents (power cables, power cords, telecommunication cables) are used to transfer electricity, they use electrical panels to create a place for them to be assembled and connected to electrical equipment. The electrical panel can be made of either metal or polymers. The electrical panel may not necessarily have a door. This means that the electrical panel can also be a closed or open box.

Access to the board can be side-by-side or without access. Due to the high risks of short circuit and protection against side and environmental errors as well as problems caused by the installation of closed electrical panel equipment. In large complexes, there should be a large distribution line for electrical conductors, including a variety of electrical wires, power cables, and electrical equipment. You must use a board to connect them. The electrical panel can be divided into several topics. Each of these electrical panels has its own function in the electrical industry

Nirutvan Abtin Company designs and manufactures electrical panels based on special methods and international standards, which must be considered before preparing the

following conditions should be considered when designing an electrical panel:

1- Environmental conditions (for operation).

2- Necessary conditions for installation.

3- Conservation conditions.

What is the applications of electrical panels?

What is the applications of electrical panels?

An electrical panel is the space in which electrical equipment is installed. In defining a electrical panel, it is not necessary to consider it a closed metal space. In electrical equipment, problems arise from the installation of equipment and hazards caused by environmental factors and phenomena such as short electrical connection. The availability of all electrified parts by the operator prompted the manufacturers to provide more safety. Based on this, the electrical panel was designed in the form of a closed chamber so that the equipment inside it was inaccessible. A electrical panel is a chamber for the installation and wiring of electronic equipment’s, boards and switches. In an electrical panel, switches and control and protection components and display accessories (voltage, current, frequency, power, etc.) are also installed.

What is the function of the electrical panel?

What is the function of the electrical panel?

In short, electrical panels can perform a variety of tasks. For example, in the face of sudden electric shocks, individuals and users can maintain an environment. In the electrical panel, various equipment’s, circuits and devices are installed for different uses. The electrical panel protects the equipment from environmental factors such as rain, snow, etc.

One of the drawbacks of distributing electricity without an electrical panel is the correct distribution of power. Despite the electrical switchboard, this is easily done. The electrical panel, despite the fuses and circuit breakers in its construction, easily distributes the current correctly and prevents current leakage. Electrical switchboards with good and standard equipment can distribute electricity properly.

How are electrical panels classified?

How are electrical panels classified?

Electrical panels have different categories, but the most important category of electrical panels is its voltage level.

■ Electrical panel classification in terms of voltage level.

■ Electrical panel classification according to the type of placement.

■ Classification of electrical panels from the structure and shape of the building.

■ Electrical panel classification in terms of power.

■ Classification of types of building electrical panels.

■ Classification of types of building electrical panels.

انواع Electrical Panel از لحاظ سطح ولتاژ:

انواع Electrical Panel از لحاظ سطح ولتاژ:

Electrical panels are divided into three categories in terms of voltage level:

1- Weak pressure electrical panel (LV) Up to 1000 V.

2- Medium pressure electrical panel (MV) From 1000 to 63000 V.

3- High pressure electrical panels (HV) From 63000 to 400000 V.

Weak pressure electrical panel:

Weak pressure electrical panel:

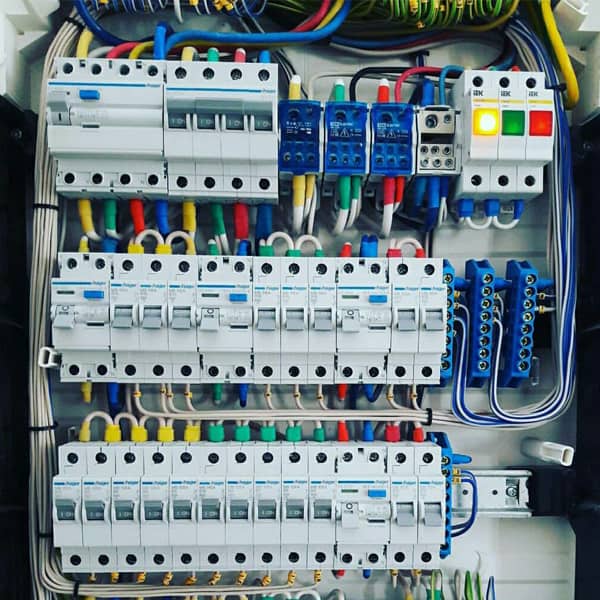

Electrical panels with a voltage level below 1000V They are called weak pressure electrical panels.

Weak pressure electrical panel according to international standard IEC60439-1 A combination of one or more devices must be disconnected and reconnected (Switching Device) Poor pressure is associated with control equipment, measurement, indicator, protection, regulator, etc. This equipment must be fully installed and mounted and all Interconnection Includes internal electrical and mechanical connections and building components. The nominal voltage of the low voltage electrical panel is usually up to 690V and the service voltages are up to 400V.

Weak pressure electrical panels are usually made in the following two types:

1- Standing sign (Fix) Fixed

2- Standing sign (Withdraw able) Sliding.

Medium pressure electrical panel:

Medium pressure electrical panel:

If the electrical panel was at the voltage level between 1000V Up to 36000V it called the medium voltage electrical panel.

The main components of a medium voltage electrical panel include body, switch (degenerator) or medium pressure contactor, relay, busbar, voltage and current transformer, measuring equipment and control equipment.

Medium pressure electrical panels are divided into two general categories:

1- Fixed medium pressure electrical panel (Fix)

2- Medium sliding pressure electrical panel (Withdraw able)

High pressure electrical panel:

High pressure electrical panel:

The electric system, which operates at temperatures above 36 kV, is known as the high voltage electrical panel. Due to the high voltage, the arc generated during keying is also very high. Therefore, special considerations are required when designing high voltage electrical panels. High voltage circuit breaker is the main element of high voltage electrical panels. Therefore, these codes must have unique features for safe operation. Errors and switches in high voltage circuits are very rare. Most of the time, these circuit breakers remain on, and they may be forced to operate after a long time. So circuit breakers must be reliable. The technology of high voltage circuit breakers has changed a lot over the past 15 years. In high voltage electrical panels, most oil, air and gas circuit breakers SF6 are being used.

Vacuum circuit breakers are rarely used in these panels because to date these circuit breakers are not suitable for short-circuit disconnection at high voltages. Two types of single pressure and two pressures for circuit breakers SF6 There is. Its single-pressure type is currently very popular in high voltage systems. Gas today SF6 as an arc neutralizer, it has the highest popularity for high voltage and high voltage electrical systems. However, this gas intensifies the impact of greenhouse gases. The destructive effect of this gas is 23 times greater than CO2. Therefore, the leakage of this gas during its periodic service should be prevented. To reduce the emission of this gas, compounds N2-SF6 and CF4-SF6 used in circuit breakers. It should be noted that no SF6 gas shouldn't come out of the circuit breaker.

Types of electrical panels in terms of structure:

Types of electrical panels in terms of structure:

■ Electrical Panel Metal Enclosed

■ Fixed electrical panel (Fix)

■ Sliding electrical panel (Withdraw able)

■ Modular electrical panel

Electrical panel Metal Enclosed:

Electrical panel Metal Enclosed:

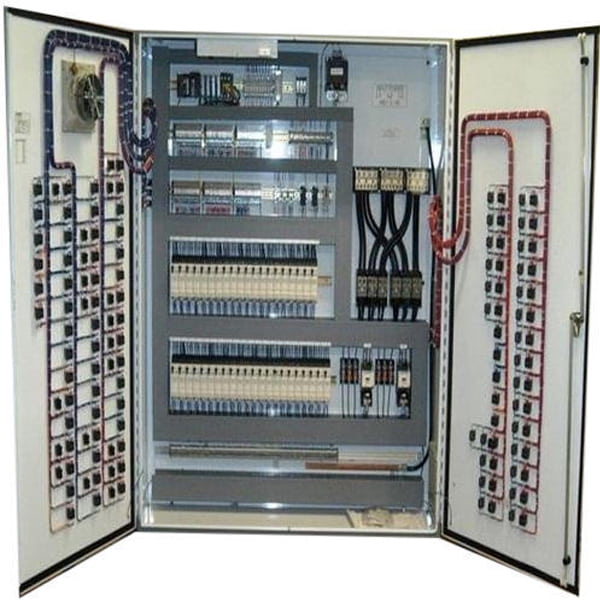

Electrical panels in the form of all-metal enclosure in which all electrical equipment, including switches, current and voltage transformers, measuring devices, etc. are installed. These electrical panels are divided into two categories:

1- Electrical panel metal clad: This type of electrical panel is a type of electrical panel Metal Enclosed There are different compartments in them. This causes that if an error occurs in one of the compartments, this error will not be transmitted to other compartments and other compartments will not be damaged and protected under its influence.

Electrical panel Metal Clad It is divided into four sections:

■ Basbar

■ Cable head chamber

■ Compartment LV (Control) in which measurement, protection and control equipment are placed.

■ Key chamber

2- Electrical panel compartment type: This type of electrical panel is a type of electrical panel Metal Enclose There are no separate compartments in them.

Fixed electrical panel (Fix):

Fixed electrical panel (Fix):

■ Multi-purpose stationary electrical panels: These panels are stationary and multi-purpose electrical panels, and inside them can be control, power, pneumatic equipment & etc.

■ Wall mounted electrical panels: These panels are divided into two categories; surface electrical panels (On Surface) And built-in electrical panel (Flush Mounting).

■ Wall mounted electrical panels: These panels are divided into two categories; surface electrical panels (On Surface) And built-in electrical panel (Flush Mounting).

■ Swing electrical panels are kind of Rack electrical panels They have a movable door and the advantage is that the back of the equipment is visible and access to the back of the equipment is provided. This model is very expensive and the door is made of glass.

Sliding electrical panels (Withdraw able):

Sliding electrical panels (Withdraw able):

■ Engine control panels (Motor Control Center (MCC): These electrical panels are made sliding and are made to control the motors. These boards are very expensive because of the advantage of sliding boards.

■ electrical panels for power center (Power Center): These electrical panels are used to feed the electrical panels MCC. They are used as a distribution board and can hold several boards MCC These keys are mostly of the air type and are used after the main post.

Modular electrical panel:

Modular electrical panel:

Advanced type of fixed stationary electrical panel. Each feeder is mounted in a panel in the form of a module and is separated from its upper and lower feeder by a metal plate and is divided into two general types in terms of access to the cable head.:

■ Access from behind.

■ Access from the front In this case, usually next to the main door of the electrical panel, a small door called the side door is installed and the cables are connected to the feeders through this door. This type of cells can be entered from above due to the entrance and exit of cables. The entrance was divided from below.

Posts related to Electrical Panel - Information and its classification

All material and intellectual rights are reserved for the NiruTavan