What is a Junction Box? What is the use of Junction Box?

What is a Junction Box? What is the use of Junction Box?

The Junction Box or junction box is used in building construction. The box includes a square box that provides protection and security barriers for electrical wiring connections or power cables. The most common use of Junction Boxes that most electricians are familiar with is in electrical installations, or in simple terms, in construction or industrial electrical wiring. In residential and commercial buildings, factories and industries, due to the existence of electricity distribution network, the Junction Box can be used. Due to the high use of Junction Boxes in many places, the material of the Junction Box can be made of metal. Or non-metallic.

The purpose of using the Junction Box is to create a safe environment for conductors or wires and power cables that need to be replaced along the way during construction. The Junction Box basically has a lid. The cap allows the Junction Box to protect wires or power cables. This cap protects the Junction Box from environmental access. The Junction Box cover can prevent dust and moisture from entering it.

A small metal or plastic Junction Box can be part of an electric conduit or wiring system for thermoplastic cable (TPS) in a building. Be. Especially in residential or commercial buildings, a suitable type can be hidden in wall plaster (although completely hidden, many are not allowed in terms of modern codes and standards) or placed in concrete. So that only its cover is visible.

Definition of Junction Box

Definition of Junction Box

The Junction Box or junction box is used in building construction. This split box includes a square box that provides protection and security barriers for electrical wiring connections or power cables. The most common use of Junction Boxes, which most electricians are familiar with, is in electrical installations, or simply in construction or industrial electrical wiring. A split box is used to distribute conductors and cross-section and protect electrical wires or cables. In residential and commercial buildings and factories and industries, electricity distribution boxes can be used due to the existence of electricity distribution network. Due to the high use of Junction Boxes in many places, the material of the Junction Box can be metal or non-metal, depending on the environment used.

Junction Box distribution material:

Junction Box distribution material:

■ Metal Junction Box.

■ Non-metallic or plastic Junction Box.

What is the reason for naming the Junction Box and the

reason for using the Junction Box code?

What is the reason for naming the Junction Box and the

reason for using the Junction Box code?

Junction Boxes have special codes. Using those codes lets us know where and how to use the Junction Box. Based on these codes, the Junction Box can resize and meet our diverse needs. The Junction Box can simply be used to protect the connection of multi-purpose wires and cover a flat plate. Junction Boxes, such as a door, are used for outputs or wall switches. Other boxes are used to hang ceiling fixtures and more.

The reason for naming it in the Junction Box (or junction box) goes back to its original use. Initially, the electrical partition box was used in the building's electrical wiring to hide connections and make connections. Today, although the use of Junction Boxes has changed a lot, it is still known by its original name, the same Junction Box. In every electrical and industrial system, there are electrical connections between different parts. These connections may be through the terminal or directly overhead. Various environmental conditions such as dust, high temperature and extreme humidity affect these connections. These connections must be housed inside a closed compartment to increase safety and prevent connection. Using a Junction Box is a good solution.

Types of boxes Electricity distribution in terms of body

material:

Types of boxes Electricity distribution in terms of body

material:

■ Aluminum Junction Box (Dicast).

■ Galvanized Junction Box.

■ Plastic Junction Box. (ABS).

■ Polycarbonate Power Junction Box

■ Anti-explosion Junction Box.

Aluminum Power Junction Box (Dicast):

Aluminum Power Junction Box (Dicast):

Aluminum Junction Box is made of aluminum alloy and is very strong and suitable for mechanical engineering and industrial automation applications. This Junction Box has special thermal and mechanical properties depending on the material of the body. This feature makes it efficient for use in industries, ports, shipbuilding, agriculture, and in general applications with difficult conditions and loads. The aluminum Junction Box prevents its internal equipment from being subject to a variety of pressures and stresses and is resistant to cold, heat and damage to roads, railways and tunnels. The electrical partition box usually has an IP66 protection class and its aluminum mold is covered by an anti-scratch electrostatic paint coating. In general, the Aluminum Junction Box is suitable for use in open, humid and high-pressure spaces.

Galvanized Power Junction Box:

Galvanized Power Junction Box:

The galvanized power partition box is a good place for electrical connections that protect the connections against the dangers of high temperatures as well as corrosion. This type of electrical distribution box protects corrosion due to the galvanized body. In this type of box, the main metal partition is covered by a layer of protective metal, which is usually made of zinc. This type of box is made of "electric partition" in two forms: hot galvanized and cold galvanized. In general, this type of box is divided into electrical parts due to its ability to protect against corrosion in open environmental conditions where there is a risk of corrosion and rust.

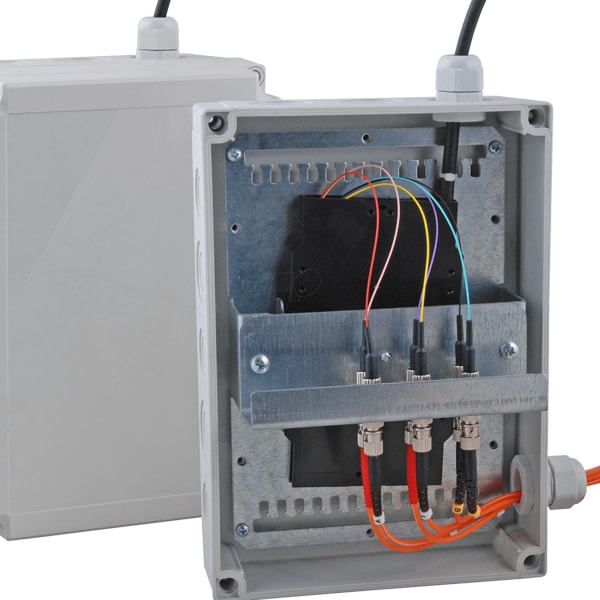

Plastic Power Junction Box (ABS):

Plastic Power Junction Box (ABS):

Plastic Junction Box is one of the most widely used boxes in the electrical industry. Its unique features compared to the box - the distribution of electricity with other body materials has increased the use of this box - the distribution of electricity in different environments and places.

The most important features of this box are "electrical partitions", mechanical strength and impact resistance, as well as high chemical resistance and electrical and thermal insulation. The strength of this box, the distribution of electricity in the sun, and its usability in environments with high humidity and dust, the use of this box has increased the distribution of electricity. In general, the reasonable price of this box, the distribution of electricity, as well as the strength and high degree of protection are the most important features of this type of box.

Polycarbonate Junction Box:

Polycarbonate Junction Box:

Polycarbonate is one of the hardest transparent and opaque plastics. Polycarbonate is a good alternative to glass and plastic in the industrial, construction and laboratory sectors. The polycarbonate Junction Box, along with the metal assembly plate, has transparent impact-resistant doors, deformation, color change, fire and electrical hazards. These Junction Boxes can be used outdoors and in humid environments. This box is usually used to distribute electricity as a switchboard to assemble power or command electrical circuits.

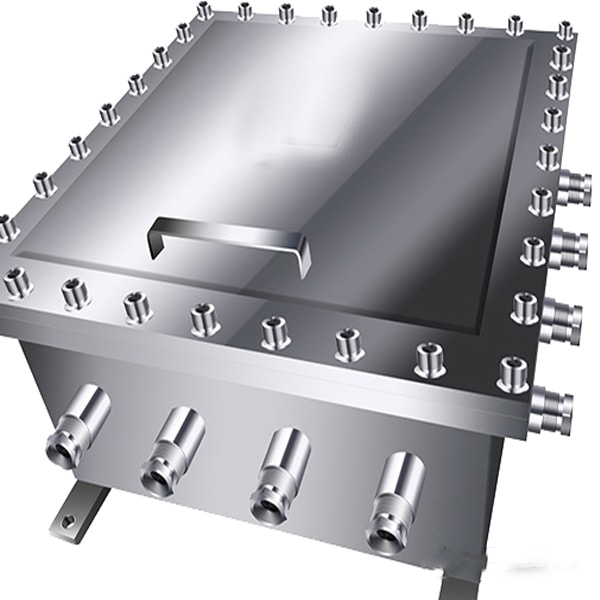

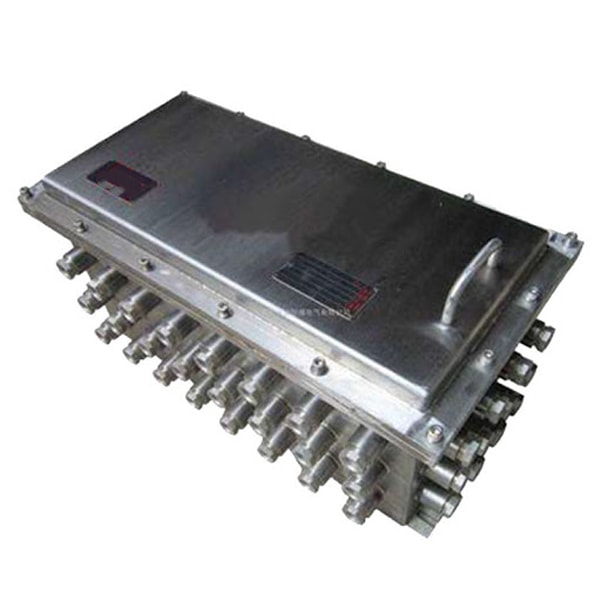

Explosion-proof Power Junction Box:

Explosion-proof Power Junction Box:

Briefly about explosion-proof junction box

Electric blasting box or so-called explosion-proof box or so-called explosion-proof housing has various electrical components such as switches, sockets, transformers and controls and handles to protect the environment from electrical hazards. This anti-spark chamber is resistant to sparks, explosions and electric shocks by using up-to-date technology. It also has the ability to withstand extreme temperatures.

Using this power splitter box is an ideal solution to prevent Excessive damage to hazardous environments is prone to explosion. Anti-explosive protection compartment is provided depending on the place of use and their level of protection. Here we describe the technical specifications of the explosion-proof Junction Box. These boxes are designed and manufactured in different dimensions.

The length of the junction boxes is from 250 mm to 720 mm.

The width of the junction boxes is from 200 mm to 560 mm.

The depth of the junction boxes is from 170 mm to 345 mm. In addition, the explosion-proof junction box can be made of aluminum, stainless steel and GRP.

Types of explosion-proof boxes:

Types of explosion-proof boxes:

■ Aluminum explosion-proof Junction Box.

■ Stainless steel explosion-proof Junction Box.

■ GRP anti-explosion junction box.

Aluminum explosion-proof Junction Box:

Aluminum explosion-proof Junction Box:

Aluminum metal blasting, blasting, waterproof and dustproof electrical distribution box suitable for installation of electrical equipment This type of aluminum anti-explosive metal Junction Box has the best type of protection against explosion-proof Junction Box with door washer, hinge and door handle, explosion-proof box in different dimensions and shapes and thickness with rail and terminal and with capability. Installation of explosion-proof signal lights Multi-mode knobs, stop and start explosion-proof, ammeter,… on the lid of the explosion-proof Junction Box. Punch and spread of all kinds of anti-explosive gold around the body of the Junction Box to the permitted and standard level of the company that produces this product. Other advantages of this type of explosion-proof and waterproof aluminum junction box, which can be mentioned, are the ability to install rails, terminals, breakers, contactors, fuses, and so on. Also in the body of this Junction Box, stainless steel bolts and nuts have been used.

Stainless steel explosion-proof Junction Box:

Stainless steel explosion-proof Junction Box:

Steel blasting Junction Box is made of stainless steel and is suitable for electrical installations. In aggressive and humid environments and environments that have corrosive substances, due to the anti-corrosion properties of steel, this type of junction box can be used. Accessories for this power-sharing box include stainless steel bolts, EPDM washers at the door junction, and internal and external screws. This Junction Box can also be used in various cases as a terminal box, junction box. Depending on the type of application, different types of drilling can be done on it. The importance of choosing the right distribution box for the relevant environment is so important that if you do not pay enough attention, there is a possibility of any irreparable risks. This type of stainless steel explosion-proof Junction Box has a washer around the door and can be used as an anti-corrosion box and is usually used as a box terminal.

GRP anti-explosion junction box:

GRP anti-explosion junction box:

The GRP explosion-proof Junction Box is made of fiber-reinforced polyester. GRP explosion-proof Junction Boxes can be installed in all industrial plants due to their resistance to fuel oil pollution and mechanical shocks, as well as their lightness and practicality, especially in cases where there is a potential risk of explosion or fire. has it. The split box door has a silicone gasket that is resistant to low and high temperatures and corrosion. This type of Junction Box is made with various thicknesses, sizes and shapes.

GRP explosion-proof Junction Box with round door washer, corrosion resistant, commonly used as a terminal box. This type of Iranian explosion-proof box is resistant to high temperatures. The material of the Iranian GRP anti-explosion Junction Box is made of polyester fibers. This type of Junction Box is made with various thicknesses, sizes and shapes....

What to consider when choosing a box for electrical

distribution?

What to consider when choosing a box for electrical

distribution?

■ Body and box material Electrical partition.

■ Dimensions of the box Electrical partition.

■ Degree of protection Electricity division.

■ Installation method Electrical partitioning.

Here are some tips to help you get started:

Here are some tips to help you get started:

Sometimes the Junction Box includes built-in terminals for connecting wires, and if a terminal is not built into the Junction Box, a rail terminal can be installed by installing a miniature rail. Installing these terminals provides the following benefits.

۱ - It prevents the wires and fittings from being cluttered, which greatly increases the security level of the fittings.

۲ - The presence of a rail terminal makes it easy to connect two or more wires or branch from one wire.

۳- Rail terminals can be fitted with numbers or labels, and you can stick a simple map of the connections inside the Junction Box on the door, or put the map inside the Junction Box so that you can easily make a problem or change the system. Control the system.

۴- The Junction Box has the ability to install gold and the wires can be passed through the gold. He then inserted them into a junction box or Junction Box. This prevents the power from being transmitted to terminals or junctions if the cables are pressurized by a foreign object.

۵- If necessary and according to the environmental conditions, it is possible to provide boxes with high IP, such as IP = 65, which usually have a plastic washer on their door. If Gland is used at the entrances and exits of wires and cables, it is not possible for dust, water and moisture to enter the terminal box after closing the lid of the Junction Box. This further protects the connections inside the Junction Box.

Posts related to Application of Junction Box Wire - Information and Classification of Junction Box Wire

All material and intellectual rights are reserved for the NiruTavan